Saving time is a recipe for success in the construction industry. Quicker installations and more efficient work processes reduce labor costs and maximize ROI. The old adage “Time is money” smacks of cliché, but every successful contractor will vouch for the veracity of this statement. Today’s post will explore how the Unistrut framing system saves time and reduces labor costs.

Let’s start with key features of the Unistrut system that help you build with confidence:

To making secure connections with Unistrut, follow these simple steps: Insert a spring loaded or regular channel nut anywhere along the length of Unistrut channel. The ability to pick any point along the section of strut gives you the maximum flexibility to make your connection. Both spring loaded and regular Unistrut channel nuts feature rounded ends for easy insertion (Illustration 1).

A 90 degree clockwise turn aligns the grooves in the nut with the inturned edges of the channel. Again, fittings can be placed anywhere along the channel opening, creating complete freedom of adjustment while eliminating the need to drill holes (Illustration 2)

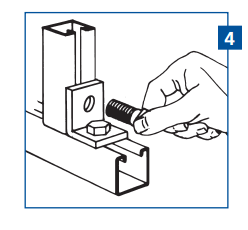

Insert the bolt through the fitting and into the channel nut and finger tighten. See illustration 5 for an end view showing the nut in place (Illustration 3).

Next, bolt the additional channel section in place by following the procedures

Tightening the bolts with an ordinary hand wrench locks the serrated teeth of the nut into the inturned edges of the channel to complete a strong, weld-free connection. If a connection needs to be moved, the adjustment is simple as loosening the nuts, sliding the assembly to a new position, and re-tightening the bolts. All connections made using the Unistrut system are 100% adjustable and re-usable with no surface prep, welding, drilling, or special tools required (Illustration 5).

The Design & Material Program

Most folks easily appreciate the advantages of the Unistrut framing system, but this isn’t always enough to convince a customer to tackle a project with

Build With Confidence

The DM program is designed to help you build with confidence. Let us take away your worries by providing expert engineering and hand picking all of your required cut-to-length channel, hardware, and fittings. Your team will work more efficiently and move quickly to their next project. Reducing labor costs and project delays are time-tested strategies to improve ROI in the construction world, but it all starts with a good plan. Eliminate costly in-field modifications and project delays by putting our years of engineering and field installation experience to work for you. To learn more about the Unistrut framing system or our Design and Material program, contact Unistrut Service Company for further assistance.

Helpful Downloads & LinksFeatures of The Unistrut SystemUnistrut Weldless Connections InfoGraphic