| Beam Loading - P5000 | ||||||

|---|---|---|---|---|---|---|

| Span (in) |

Max Allow. Uniform Load (lbs) |

Deflection at Uniform Load (in) |

Uniform Loading at Deflection | Lateral Bracing Reduction Factor | ||

| Span/180 (lbs) |

Span/240 (lbs) |

Span/360 (lbs) |

||||

| 24 | 5,260 | 0.03 | 5,260 | 5,260 | 5,260 | 0.98 |

| 36 | 3,500 | 0.07 | 3,500 | 3,500 | 3,500 | 0.85 |

| 48 | 2,630 | 0.12 | 2,630 | 2,630 | 2,630 | 0.70 |

| 60 | 2,100 | 0.18 | 2,100 | 2,100 | 1,920 | 0.55 |

| 72 | 1,750 | 0.26 | 1,750 | 1,750 | 1,330 | 0.44 |

| 84 | 1,500 | 0.36 | 1,500 | 1,470 | 980 | 0.38 |

| 96 | 1,310 | 0.47 | 1,310 | 1,120 | 750 | 0.33 |

| 108 | 1,170 | 0.59 | 1,170 | 890 | 590 | 0.30 |

| 120 | 1,050 | 0.73 | 960 | 720 | 480 | 0.28 |

| 144 | 880 | 1.06 | 670 | 500 | 330 | 0.24 |

| 168 | 750 | 1.43 | 490 | 370 | 240 | 0.22 |

| 192 | 660 | 1.88 | 370 | 280 | 190 | 0.21 |

| 216 | 580 | 2.35 | 300 | 220 | 150 | 0.19 |

| 240 | 530 | 2.95 | 240 | 180 | 120 | 0.18 |

| Note | Bearing load may govern capacity. | |||||

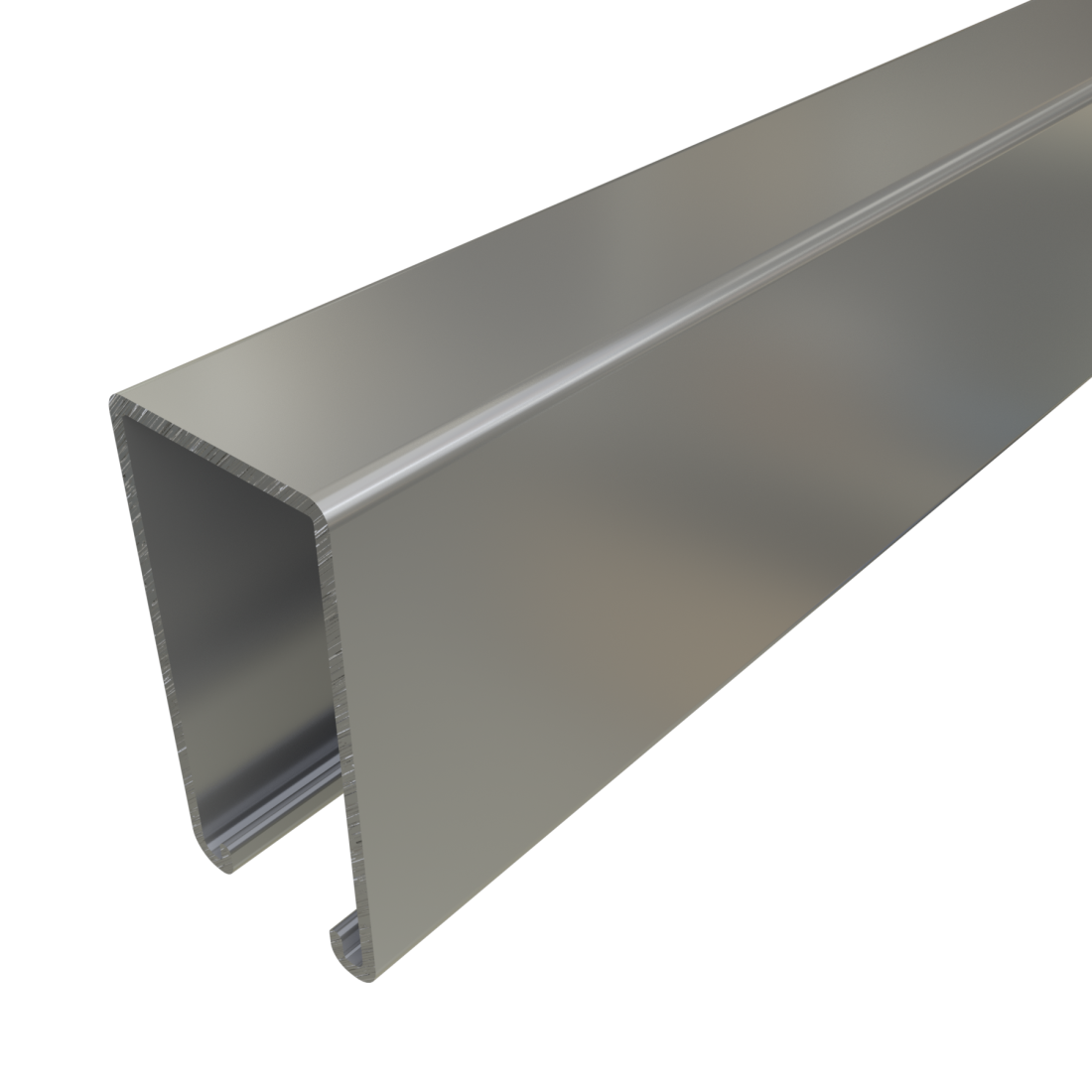

Unistrut

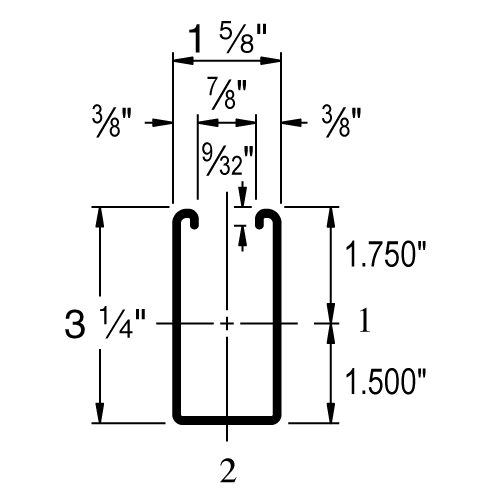

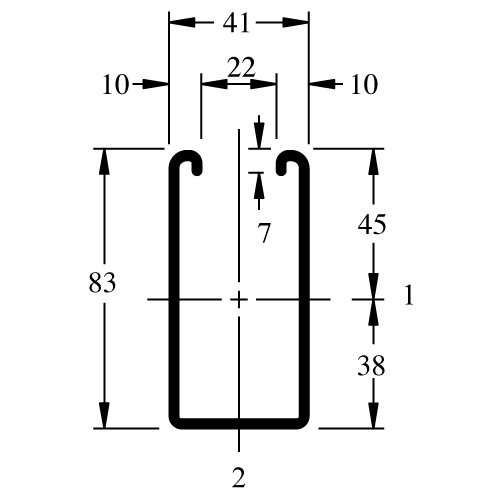

Unistrut P5000 - 1-5/8" x 3-1/4", 12 Gauge Metal Framing Strut, Solid

CUT TO A CUSTOM LENGTH? MAY SAVE ON SHIPPING

HOW WOULD YOU LIKE IT CUT?

Some cutting jobs allow us to use ground shipping rather than LTL, yielding significant freight savings. A customer service associate will contact you to confirm the cut list and shipping and freight costs prior to finalizing your order. eg - 4 cuts per stick x 5ft per section

Features:

- Product dimensions are 1 5/8" wide x 3 1/4" tall x 12 ga. thick, solid.

- Punched holes are also available for ease of installation

- The advantage of a deeper, heavier gauge profile is to support heavier loads and mitigate deflection under load.

- OPM pre-approved for seismic applications

- UL and CSA listed

- Our P5000 is available in the following finishes: Pre-Galvanized (PG), Unistrut Defender (DF), Hot-Dip Galvanized (HG), Plain (PL), Green (GR), Zinc Dichromate (ZD) and Stainless Steel (SS or ST).

- Made in the USA

Beam Loading

Column Loading

| Column Loading - P5000 | |||||

|---|---|---|---|---|---|

| Unbraced Height (in) |

Allowable Load at Slot Face (lbs) |

Max Column Load Applied at C.G. | |||

| K=0.65 (lbs) | K=0.80 (lbs) | K=1.0 (lbs) | K=1.2 (lbs) | ||

| 24 | 5,650 | 16,870 | 15,180 | 12,850 | 10,600 |

| 36 | 4,690 | 13,140 | 10,600 | 7,650 | 5,660 |

| 48 | 3,560 | 9,550 | 6,860 | 4,790 | 3,660 |

| 60 | 2,730 | 6,680 | 4,790 | 3,450 | 2,710 |

| 72 | 2,160 | 4,980 | 3,660 | 2,710 | 2,170 |

| 84 | 1,760 | 3,950 | 2,960 | 2,240 | 1,820 |

| 96 | 1,500 | 3,270 | 2,500 | 1,930 | 1,580 |

| 108 | 1,310 | 2,800 | 2,170 | 1,690 | 1,390 |

| 120 | 1,170 | 2,450 | 1,930 | 1,510 | KL/r>200 |

| 144 | 980 | 1,980 | 1,580 | KL/r>200 | KL/r>200 |

| 168 | 850 | 1,670 | 1,340 | KL/r>200 | KL/r>200 |

Elements of Section

| Elements of Section - P5000 | ||

|---|---|---|

| Area of Section | 0.897 in2 (5.8 cm2) | |

| Axis 1-1 | Axix 2-2 | |

| Moment of Inertia (I) | 1.098 in4 (45.7 cm4) | 0.433 in4 (18 cm4) |

| Section Modulus (S) | 0.627 in3 (10.3 cm3) | 0.533 in3 (8.7 cm3) |

| Radius of Gyration (r) | 1.107 in (2.8 cm) | 0.695 in (1.8 cm) |

General Specifications

Standard Lengths:

- 10 feet: 10' or 10’ 1/8” (3.05m) ± 1/8" (3 mm)

- 20 feet: 20' or 20’ 3/8” (6.11m) ± 1/8" (3 mm)

Special Lengths:

- Available with a tolerance of ±1/8" (3 mm). Request quote.

Load Data:

- All beam and column load data pertains to carbon steel and stainless steel channels.

- Load tables apply only to UNISTRUT brand channel. Look for "UNISTRUT" on the product.

- Load tables and charts are constructed to be in accordance with the SPECIFICATION FOR THE DESIGN OF COLD-FORMED STEEL STRUCTURAL MEMBERS 2007 EDITION published by the AMERICAN IRON AND STEEL INSTITUTE USING ASD METHOD.

- Loads are based on 33 ksi steel cold formed to 42 ksi.

- Safety Factor to Yield Strength is 1.67 for Beam Loads and 1.80 for Column Loads.

- Beam loads are based on a simple beam and are given as a total uniform load (W) in pounds. For proper calculation procedures, refer to our Beam Load Calculation Guide under Resources.

- For bearing loads, reference our Bearing Loads Page.

Materials & Finishes

Materials & Finishes - Standard:

- Pregalvanized (PG): Conforms to ASTM A653 SS GR 33, G90.

- Unistrut Defender (DF): Conforms to ASTM A1046 SS GR 33

- Hot Dip Galvanized (HG): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM A123

- Perma-Green (GR): Steel conforms to ASTM A1011 SS GR 33, E-Coat finish

- Perma-Gold (ZD): Steel conforms to ASTM A1011 SS GR 33, Finish conforms to ASTM B633, Type II SC3

- Plain (PL): Conforms to ASTM A1011 SS GR 33

- Stainless Steel, Type 304 (SS): ASTM A240, Type 304 *

- Stainless Steel, Type 316 (ST): ASTM A240, Type 316 *

- Aluminum (EA): ASTM B221, Type 6063-T6 (Extruded) *

* These materials have different physical properties and performance characteristics. Please contact us for design support.